In the application of electric vehicles, in addition to battery-driven vehicles, batteries will also be used to drive the air conditioning compressor to provide cooling and heating for electric vehicles. This article will show you the 320V and 3500W high-voltage air conditioning compressor solutions introduced by Arrow Electronics for your reference in product design.

Rapid development of electric vehicles drives a change of generation

In recent years, automobiles have moved towards the development of hybrid and pure electric modes, and electric vehicles are facing strong market demand. Many emerging brands of electric vehicle companies are capturing market share at this time of change. Facing market demand and pressure, traditional large automobile factories are also actively transforming towards electric vehicles, making the electric vehicle market flourish.

The main difference between electric vehicles and fuel vehicles lies in the different driving methods, i.e., fuel vehicles use fuel engines to drive vehicles, while electric vehicles use battery-driven motors to drive vehicles. Other vehicle structures are basically the same, including many intelligent applications, such as automatic assisted driving and on-board infotainment systems, which are also applicable to traditional fuel vehicles and are not the exclusive features equipped in electric vehicles.

Battery-driven air conditioning compressor for electric vehicle

The air conditioning system of electric vehicles is basically the same as that of traditional fuel-powered vehicles. It is composed of a compressor, condenser, evaporator, cooling fan, blower, expansion valve, liquid storage dryer, high and low pressure pipeline accessories, sensors, etc. However, the traditional vehicle compressor is driven by the engine transmission belt through the electromagnetic clutch, while the electric vehicle use an electric compressor integrating the motor, compressor and circuit to drive the air conditioner, and the electric vehicle compressor is driven by high voltage electricity provided by the power battery.

The electric vehicle compressor is operated directly by the electric energy of the power battery pack. A control device is arranged in the compressor, and the rotational speed of the compressor is controlled by receiving signals directly from the outside. Compared to the compressor of the traditional fuel engine vehicle, it is not subject to engine speed, allowing the air conditioning system in the vehicle to operate independently, which does not increase the burden on the power system on the one hand, and the compressor can operate at high speed on the other hand, so a compressor with small footprint can be used to reduce power consumption, thus prolonging the endurance of the electric vehicle.

The cooling and heating modes of electric vehicles are quite different

A fuel vehicle uses the engine to push the generator set to charge the battery, which then supplies power to the air conditioner compressor for operation, thus realizing the work on the refrigerant and achieving the refrigeration effect. Moreover, as the engine will generate waste heat during operation, a fuel vehicle can make full use of this heat to heat the coolant and realize the heating in the vehicle.

The air conditioner of the electric vehicle is driven by the battery. Through a DC/DC converter, the high-voltage direct current of the battery is converted into low-voltage direct current, thus supplying electricity to the electric compressor or other air-conditioning components to ensure the operation of the air-conditioning components. The low-voltage converted current provides power to the electric vehicle compressor and performs work on the refrigerant, thus achieving the refrigeration effect. Moreover, due to the lack of an engine in the electric vehicle, the waste heat generated by the operation of the vehicle cannot be utilized in the heating mode, so it is necessary to generate heat by itself or assist the external heat conversion to realize the heating in the vehicle.

Automotive-grade chips provide complete protection

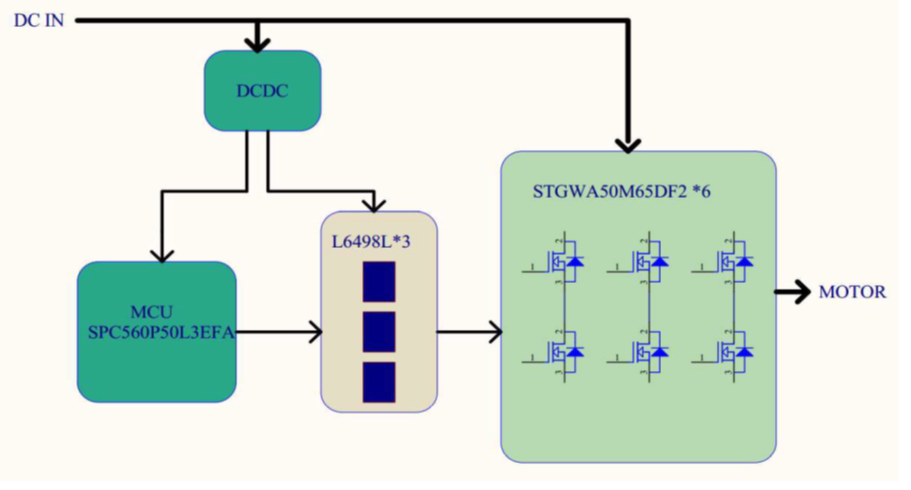

In order to improve the development speed of electric vehicles, Arrow Electronics has introduced a reference design for high-voltage air conditioning compressors. The circuit board is designed for electric vehicles using 320V batteries and can support high-voltage electric vehicle compressors. In this design, an automotive-grade SPC560 is used as the controller. The input voltage of the board is 320V and the output power can be up to 3.5kW. It has high-efficiency and high pressure start-up, low noise, speed closed-loop control, and supports overvoltage, undervoltage, overcurrent and overtemperature protection.

The reference design uses ST's SPC560P50L3EFA microcontroller, L6498L gate driver, STGWA50M65DF2 IGBT transistor and other core chips, which can be compatible with 1000-6000 rpm BLDC/PMSM/IPM compressors, has 96% operating efficiency, supports sensorless FOC control algorithm, and supports CAN, LIN and PWM control, and can be applied to products such as car refrigerator compressors and air conditioning compressors.

Conclusion

With the rapid development of electric vehicles, the demand for electric vehicle air-conditioning compressors is also rising and market demand is high. Arrow Electronics has introduced a reference design for electric vehicle air-conditioning compressors using best-in-class chips, which can speed up the product development process and assist manufacturers to seize market opportunities as soon as possible. It is worthy of in-depth understanding by manufacturers interested in entering relevant application fields.