There are more and more battery-powered devices in the market. Improving the operation efficiency of batteries and recycling secondary batteries for more applications is an important development direction at present. This article will show you the operation of battery formation system, the reuse of second life batteries, the application development of solar photovoltaic system, and related solutions.

Efficient battery formation system with energy recycling capability

Due to more and more battery-powered applications, especially electric vehicles (EV) and portable devices such as smartphones, tablets and power tools, the global demand for lithium-ion batteries is increasing. The battery formation process activates lithium chemistries through precisely controlled charging and discharging cycles, and transforming the chemistries into usable format. Therefore, the battery formation system needs high power density to increase the charging and discharging channels and efficient power conversion with energy recycling capability, bidirectional power processing.

The system formed by the power supply from the AC grid to the formatted battery will include a power factor correction (PFC) stage as the AC grid interface, an isolated DC-DC stage for current isolation and step-down, and a non-isolated DC-DC stage for providing tight charge and discharge voltages for well-controlled of charge and discharge currents. All stages are based on switching converter technology rather than linear regulators. The switching converter approach allows the formation system to improve energy efficiency, power density, and provides the possibility of energy recycling using the same hardware, thereby reducing battery manufacturing costs.

In order to meet the high power density, high efficiency and energy recycling requirements of reliable battery formation systems, Infineon provides a variety of products, including power devices, driver ICs and microcontrollers. The core stage of the battery formation system can be divided into the PFC stage, isolated DC-DC stage and non-isolated DC-DC stage.

Infineon recommends using the 600 V CoolMOS™ C7 and P7 series as active switches in these PFC topologies for efficient power conversion. The CoolSiC™ Schottky Diode 650 V G6 is the recommended passive switch, providing only a forward voltage drop of 1.25 V, reducing conduction losses at the PFC stage.

Like the high-efficiency server switching mode power supplies (SMPS) design, zero-voltage switching (ZVS) topology is usually applied to the isolated DC-DC stage of the battery formation system. Two typical topologies are half-bridge LLC and ZVS phase-shifted full-bridge converters. According to controller selection, Infineon recommends 600 V CoolMOS™ CFD7, P7 and C7 as LLC primary side MOSFETs.

The formation system controller instructs the non-isolated converters to charge their respective batteries, and usually starts the discharge process at a similar time with other non-isolated converters of the system. Depending on the converter's switching frequency, the designer can choose the most suitable Infineon family. StrongIRFT™ is recommended when the switching frequency is equal to or is below 100 kHz, while OptiMOS™ 5 provides less power loss at switching frequencies above 100 kHz.

Energy storage system solves the problem of the second life battery of electric vehicles

Energy storage has always been an indispensable part of power generation, transmission, distribution and consumption. With the continuous growth of renewable energy generation, the power pattern is undergoing tremendous changes. Energy Storage System (ESS) provides a wide range of technical methods to manage supply and demand, create a more flexible energy infrastructure, and bring cost savings to utilities and consumers. Battery-based ESS technology can respond to power outages in less than a second, harnessing clean energy from collocated solar or wind plants.

Infineon's unique expertise in energy generation, transmission, power conversion and battery management makes it the perfect partner to advance ESS solutions in terms of efficiency, innovation, performance and optimal cost. Infineon's unique expertise and product portfolio provide state-of-the-art solutions that reduce design effort, improve system performance, speed up time to market and optimize system costs.

The three key trends of ESS are silicon carbide (SiC), multi-modular approach of second life batteries and development of battery management system (BMS). The newest member of Infineon's SiC portfolio, the CoolSiC™ MOSFET 650 V family, is the product of the most advanced, optimized trench semiconductor process, which is uncompromising in achieving the lowest loss in applications and the highest reliability in operation.

In an era of the increasing popularity of electric vehicle solutions, it is foreseeable that the world will have to deal with a large number of used electric vehicle batteries in the future. One of the main advantages of modularly cascaded and multilevel architecture is that it can realize the second life of batteries. For example, it is suitable for batteries that have reached the end of their life cycle and can no longer be used in electric vehicles. In order to solve the problem of eliminating batteries in electric vehicles, Infineon has developed modularly cascaded and multilevel architectures, which take advantage of the advantages of high-efficiency and low-voltage MOSFETs such as Infineon's market-leading OptiMOS™ family.

The battery management system implements two top-level functions in ESS applications, namely battery protection and battery monitoring, and Infineon's battery management product line and reference design, which can help successfully develop more efficient, lasting and reliable battery-powered applications. Infineon's TLE9012AQU is a multi-channel battery monitoring and balancing system IC designed for lithium-ion battery packs used in automotive, industrial and consumer applications. The TLE9012AQU implements four main functions: cell voltage measurement, temperature measurement, cell balancing, and isolated communication with the main battery controller. In addition, TLE9012AQU provides the necessary diagnostic tools to ensure the proper function of the controlled battery and detect any faults.

Bidirectional DC/DC converter for photovoltaic energy storage

In the 21st century, electric energy has become an indispensable part of our life and work. The traditional primary energy mainly used by humans is fossil energy such as oil, natural gas and coal. Fossil energy has been gradually exhausted in the rapid development and progress of human society and science and technology for more than 100 years.

In addition to the impact of the energy crisis, using traditional primary energy to generate electricity will emit a large amount of acid gases such as CO2, SO2 and NOx into the atmosphere, increasing the amount of acid rain around the world cause greenhouse effect. The combustion of traditional energy for power generation will also cause serious smog, which will harm plants and the human body.

Solar energy in green energy is an important key to solving the energy problem. There are two main structures of the photovoltaic energy storage system: MPPT + bidirectional Buckboost + PCS, MPPT + DC/DC + PCS. The difference between them is that the back end of bidirectional Buckboost is connected with a high voltage battery and the back end of bidirectional DC/DC is connected with a low voltage battery.

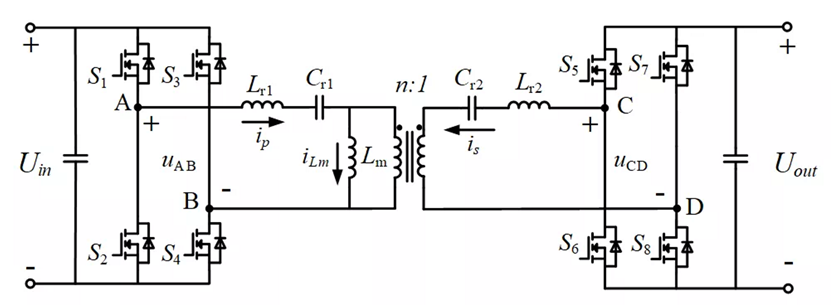

A bi-directional DC/DC converter is a two-quadrant operation of DC/DC converter. Its input and output voltage polarity are unchanged, and the input and output current direction can be changed. Generally speaking, bidirectional DC/DC can be divided into isolated and non-isolated types. Isolated bidirectional DC/DC converters are widely used, and circuit topology has many conversion forms.

At present, the bidirectional DC/DC of photovoltaic energy storage part mostly adopts CLLC of conversion circuit and phase-shifted full-bridge topology. Most of the power devices in DC/DC are IGBT, and the switching frequency is controlled at about 20K. Arrow Electronics and chip manufacturers have developed the DC/DC part design of a pure SIC scheme, which can achieve the switching frequency of 200K and an efficiency of 96%.

Arrow Electronics introduced a bidirectional power converter reference design for energy storage, which includes totem pole PFC + CLLLC topology. It works at high switching frequency with SiC MOSFET to achieve high efficiency and reduce size and weight. It can be used in high-power charging systems, such as UPS and solar energy systems. This reference design can help users speed up the design of the SiC MOSFET system and significantly shorten the product development cycle.

Compared with the IGBT design, the reference design of the bidirectional power converter of Arrow Electronics has a 50% reduction in size, with high output power (maximum 6.6 kW) and high efficiency (> 93%), supports digital control bidirectional output, reinforced isolation, and workable firmware is ready, supports AC/DC bidirectional power conversion, the maximum charging power up to 6.6kW, and supports AC input voltage from 200Vac to 265Vac 50Hz, DC output voltage from 60Vdc to 90Vdc, the maximum inverter power up to 6.6kW, the inverter rated input of 80Vdc, and the inverter rated output of 220Vac 50Hz.

High-efficiency LLC power module demonstration board

The EPC9149 demonstration board, introduced by EPC, is a 1 kW, 48 V input to 12 V output LLC converter that can be used as a DC transformer with a fixed conversion ratio of 4:1. It features 100 V rated EPC2218 and 40 V rated EPC2024 GaN FET, uP1966A and LMG1020 gate drivers, and a Microchip dsPIC33CK32MP102 16-bit digital controller. The EPC9149 demonstration board has a peak efficiency of 97.5% at 400 W, a full load efficiency of 96.7% @ 12 V, an output of 83.3 A, a size of 22.9 × 58.4 mm (0.90 × 2.30 inches), a low profile design, a total converter thickness of 10 mm without heatsink, a maximum temperature rise of 70 ℃ @ 12 V when the heatsink kit is installed, 83.3 A output, a fixed switching frequency of 1 MHz, soft startup to full resistive load support, and a high power density (excluding pins) of 1227 W/in3.

This converter is for evaluation purposes only and is not a fully functional converter and cannot be used in the final product. The EPC9149 has primary side full-bridge and dual secondary side center-tapped half-bridge configurations based on the EPC2218 and EPC2024 eGaN FETs. The EPC9149 board also includes house-keeping power supplies for logic and gate drivers, powered by the main input supply voltage of the LLC board. The input and output voltages of the EPC9149 board are measured by the resistor dividers and fed back to the microcontroller for control purposes. The module uses a customized transformer core made of ML91S material of Hitachi Metals. The core loss is low during high frequency operation. Two half core parts are inserted from the top and bottom of the board, and appropriate spacers are added in the middle to realize the required magnetizing inductance.

Thermal management is very important to ensure correct and reliable operation, and EPC9149 is used for bench evaluation at normal ambient temperature. Adding a heat-spreader or heatsink and forced air cooling can significantly increase the rated current of power devices. Still, care must be taken not to exceed the absolute maximum chip temperature of 150℃.

The EPC9149 LLC power module has a Microchip DSPIC33CK32MP102 digital signal controller DSC. This 100 MHz single core device comes with a dedicated peripheral module for switching mode power supply (SMPS) applications, Such as feature-rich 4-channel (8x output), 250 ps resolution pulse width modulation (PWM) logic, three 3.5 Msps analog-to-digital converters (ADC), three 15 ns propagation delay analog comparators with integrated digital-to-analog converters (DAC), support for ramp signal generation, three operational amplifiers, and a digital signal processing (DSP) core with tightly coupled data paths for high performance real-time control applications. The devices used are the smallest derivative of the dsPIC33CK single-core and dsPIC33CH dual-core DSC family. The devices used in this design are in a 28-pin 4x4 mm UQFN package and are specified for ambient temperatures from -40℃ to +125℃.

Conclusion

The power conversion system is the basis of all electronic design, by changing the type of current, voltage changes, to meet the needs of various applications. The various solutions introduced in this paper, mainly focusing on the establishment of battery systems and photovoltaic systems, are the hottest application directions at present. The market potential is hugely impressive, which deserves your further in-depth understanding.