Electric vehicles (EVs) have become the most important development trend in the automotive industry. Battery charging time and range are key to consumers' willingness to purchase EVs. The Battery Management System (BMS) for EVs has also become a key module for EV development. This article will show you the direction of BMS development and related products introduced by Infineon, as well as the functional characteristics of the BMS reference designs introduced by Arrow Electronics.

BMS is a key device for battery charging and discharging

BMS is an electronic control circuit that monitors and regulates battery charging and discharging. It is an electronic device that can transmit information about battery status, including detection of battery type, voltages, temperature, capacity, state of charge (SoC), state of health (SoH), power consumption, remaining operating time, charging cycles, and some more characteristics to the host system, and perform battery management.

The BMS of Li-ion batteries must monitor battery voltage and temperature to perform key functions such as battery balancing. Accurate battery voltage measurement will also ensure that batteries can operate under safe operating conditions to meet functional safety requirements. Charging may become unstable due to an overvoltage, undervoltage, or overcurrent of some chemical components of the battery. Therefore, the BMS ensures that the batteries in the system remain in the state of aging (SOA) of a given chemistry, it provides voltage and temperature measurements for each battery through an external resistor (NTC), conducts battery balancing, and transmits the measurement results and diagnostic information to the main microcontroller.

The task of a BMS is to ensure optimal use of the remaining energy in batteries. To avoid improper charging and discharging of batteries, a BMS protects batteries from deep discharging and overvoltage as a result of extremely fast charging and extremely high discharge current. In the case of multi-cell batteries, BMS also provides a cell balancing function to manage different cells so that they have the same charging and discharging requirements.

BMS improves the safety and functionality of EVs

BMS can be used to monitor and control batteries used in many applications, and battery balancing ICs are a critical factor for safety and functionality wherever used. BMSs can be widely used in EVs, including non-road vehicles such as EVs, trucks and golf carts, as well as machinery such as forklifts. BMSs can also use batteries for standby power supplies such as grids and industrial power infrastructure (cell phone towers, A/C power substations, Internet infrastructure, aviation support systems, tower communications, and weather stations). In addition, there are a growing number of consumer products, such as electric bicycles and other leisure vehicles, that need to be powered by batteries and rely on BMS for efficient and safe use.

Infineon provides optimized battery management solutions for battery monitoring and balancing applications. Battery management ICs, also known as battery balancing ICs or battery monitoring ICs, are critical to the overall health of many automotive systems.

Infineon's battery management IC can be used for safety-related applications, and automotive BMS solutions meet safety requirements up to ASIL-D and are ISO26262 compliant. Infineon’s battery management ICs are designed to work together with the AURIX™ family of microcontrollers and functional safety capable PMICs. This provides a full solution for voltage and temperature sensing, as well as balancing and communication across a variety of battery solutions.

Battery monitoring devices improve efficiency and safety of battery operation

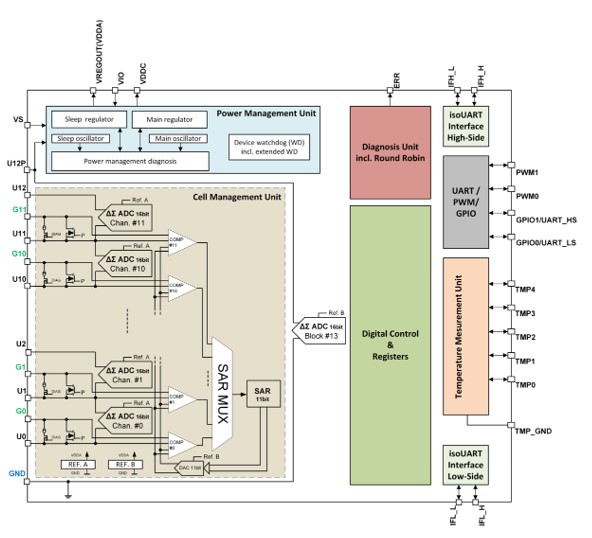

The TLE9012DQU, introduced by Infineon, is a multi-channel battery monitoring and balancing IC designed for Li-Ion battery packs. TLE9012DQU is a multi-channel battery monitoring and balancing system IC is designed for Lithium-Ion battery packs used in various applications across automotive, industrial, and consumer products. The module fulfills four main functions: cell voltage measurement, temperature measurement, cell balancing and isolated communication to main battery controller. Additionally, TLE9012DQU provides the necessary diagnostic tools to ensure proper function guaranteeing the safety of the persons around the controlled battery.

TLE9012DQU can monitor voltage of up to 12 battery cells connected in series and support hot plugging. Each cell has dedicated 16-bit delta-sigma ADC with the selectable measurement mode. It supports high-accuracy measurement for SoC (State of Charge) and SoH (State of Health) calculation. It has integrated stress sensor with digital compensation algorithm and temperature-compensated measurements, and secondary ADC with same averaging filter characteristics as advanced end-to-end safety mechanism. It has five temperature measurement channels for external NTCs and internal temperature sensors. Integrated balancing switch allows up to 200 mA balancing current.

TLE9012DQU supports differential robust serial 2 Mbit/s communication interface. It has additional four GPIO pins to e.g. connect an external EEPROM. Internal round-robin cycle routine triggers the majority of diagnostics mechanisms. It supports automatic balancing over- and undercurrent detection scheme, automatic open load and open-wire detection scheme and automatic NTC measurement unit monitoring scheme. It also supports end-to-end CRC secured iso UART/UART communication and emergency mode for communication. It is ISO 26262 safety element out of context for safety requirements up to ASIL D and a green product (RoHS compliant).

TLE9012DQU features best-in-class application robustness, best performances guaranteed by Infineon technology and device architecture under noise, the lowest system cost, small package (TQFP-48) and high feature integration for a lean external BOM.

Reference design of full-fledged BMS

Arrow Electronics launched the BMS reference design for electric vehicles applications. BMS is an electronic control circuit that monitors and regulates battery charging and discharging. The reference design consists of Infineon's powerful automotive grade Traveo II MCU CYT2B97, AFE TLE9012D, and transceiver TLE9015D. TLE9012DQU fulfills four functions: cell voltage measurement, temperature measurement, cell balancing and isolated communication, while TLE9015D is used as a transceiver to connect TLE9012DQU and MCU main battery controller. In addition, the solution integrates pressure detection, RTC, and system voltage and current sensing functions.

This BMS reference design has the advantages of reducing costs, optimizing size, reducing software effort and shortening time-to-market. It can balance and monitor up to 12 battery cells connected in series. It has a 12-channel dedicated 16-bit delta-sigma ADC battery voltage monitor with an accuracy of about 5.8 mV. 7μS fast and synced cell voltage sampling with 2Mbit/s iso-UART is used. It has an internal current balance of up to 200mA and 5-channel temperature sensors. Pressure sensors and external RTCs can be reserved to support system voltage and current sensing.

BMS reference design adopts the following core chips: Infineon’s CYT2B97CACES, TLE9012DQU, TLE9015DQU, TLE9014SH, TLE9351VSJ, KP256TMA, S6BP201A1AST2B20A, and ADI’s AD8601WARTZ, TL6654AHS6-1.25#WTRMPBF, LT8301ES5#WTRMPBF, and Skywork’s Si8931D-IS4 and Si8921BD-IS4, and Bourns’ SM91502ALA, SRP3020TA-2R2M, CDSOT23-T24CAN, SRF3225TAFD-101Y, SRF9045A-701Y, SM8S24CA-Q, as well as Molex’s 348260160, 348240164, 348260240, 348240244, 5023520200 and 5023510200 for HEV, PHEV, BEV, etc.

Conclusion

Battery management for EVs plays a key role in vehicle safety and efficiency and greatly improves EVs' safety, charging, and discharging efficiency, helping more consumers move from fuel vehicles to EVs and further expanding the market share of EVs. BMS solutions introduced by Infineon, as well as BMS reference designs introduced by Arrow Electronics, will help relevant manufacturers develop products with better performance and greatly improve product development speed. They are worthy of your in-depth understanding and adoption.