We’ve all had experiences with contamination and wear ruining the function of device controls, and by extension also ruining your experience as the user.

Maybe it was that one button on a keyboard or music player that refused to work, being greeted by loud static when you turned up the stereo, or a flaky control in your car that made your dashboard lights flicker between bright and off unless you found the one spot where everything worked (until you went over a bump, anyway!)

Whatever our background, we’ve all experienced a time when knobs, sliders, or other controls were dirty or contaminated, and even if you had the know-how to disassemble the device and clean out the contaminants, it always seemed to be a short-term fix and never actually resolved the underlying problem. While the examples so far have been mere inconveniences, the same issues can cause actual harm or significant financial loss if contaminated controls are connected to medical devices or industrial controls.

Capacitive and Inductive Sensing Technology

Fortunately, TI’s innovations in capacitive and inductive sensing have made problems like these obsolete by allowing electronics and control circuitry to reside behind sealed panels with no moving parts. Capacitive touch buttons typically use one or more circuit-board based sensors to detect disturbances in electric fields corresponding to a user’s touch on a control panel. For wheels and sliders, several sensors are used, and the relative e-field disturbance at each sensor is digitized to allow comparison & determination of the exact location of the user’s touch. Capacitive gesture sensing is based on a similar concept as sliders and wheels, but the sensors and calibration settings are configured such that the movement of a user’s hand near the interface is sufficient to register the command.

Capacitive sensors can also be used to detect deflection on conductive surfaces such as stainless steel, thereby allowing button arrays to be implemented on metal panels. Proximity sensing and liquid detection are other applications that are well suited to capacitive sensing. Depending on the configuration and the associated circuitry, proximity sensing has the ability to operate as far as 50cm away, and liquid detection can be used to detect the presence or levels of regular fluids as well as conductive liquids like soaps, detergents, and inks.

Inductive sensing, on the other hand, uses small coils or loops on a circuit board to detect small changes in AC magnetic fields. Inductive sensing can also be used for button controls, but generally supports thicker conductive panels and higher resolution. Current Inductance to Digital Converters (LDCs) such as TI’s LDC1614 can detect metal deflections of less than 1µm.

Wheels and sliders using inductive sensing can also be implemented with higher absolute precision, and inductive sensing is an ideal choice for precision axial and rotational sensing as its higher resolution enables precise position sensing even when the objects measured are above the mounting panel. Inductive sensing is also a great solution for proximity-based switching when high immunity to noise, contaminants, and static magnetic fields is desired, and event and gear counting is possible with the same immunity characteristics.

Proximity Sensing Uses

The uses for these sensors span several different applications and target markets.

• Thermostats and building controls can use proximity sensing to turn on displays when people walk by, and touch controls can be leveraged to enable an elegant interface

-

• Electronic locks can leverage capacitive and inductive controls to provide extended battery operation and ensure that lockouts do not occur due to a dead button

-

• Streamlined interfaces on consumer electronics and personal devices

-

• Automotive switches, buttons, and knobs can become wearout- and contaminant-proof

-

• Elegant control panels on appliances and other white goods

-

• Wear and contaminant proof controls for industrial systems

-

• Anti-tamper sensors and touch controls for utility meters

-

• Medical devices that can be easily wiped down without compromising device use or reliability

TI Captivate Microcontrollers for Capacitive Sensing

TI’s MSP430FR253x and MSP430FR263x family of FRAM based CapTIvate™ Microcontrollers allows designers to develop elegant and highly functional touch and proximity based user interfaces for the above applications. They support glove friendly capacitive touch, metal touch, and 3D gestures in a self-contained analog front-end, and the MCU reserves sufficient processing power to drive an LCD or LED display without degrading sensor performance. These ultra-low-power MCUs support up to 16 self-capacitance electrodes or 64 mutual-capacitance electrodes, up to 30-cm proximity sensing, and high accuracy that can measure differences as low as 1 fF. Four 16-bit timers are included, as well as two serial interfaces that can support UART, IrDA, SPI, and I²C, a hardware multiplier, RTC module with alarm capabilities, and a 10-bit ADC. They also have TI’s CapTIvate™ technology baked in to allow several advantages over competing technologies:

• Low power FRAM and zero-CPU wake-on-touch capability only require about 0.9 μA per sensor for the first four sensors, as compared to a typical 20 μA per sensor on competing products. Additional sensors only consume about 1.7 μA.

-

• Support for buttons, wheels, and sliders, in addition to proximity sensing and gestures.

-

• Advanced noise immunity that resists 10V/m electric fields and disturbances from 4kV ESD and EFT disturbances (per the IEC 61000-4 series of immunity tests).

-

• Self or mutual capacitance and proximity sensing.

-

• Support for plastic, glass, and metal overlays.

Background on TI Reference Designs

To assist in rapid design development, TI has provided several technical resources including the innovative TI CapTIvate™ Design Center. The design center allows designers to configure and calibrate their designs in under five minutes, and several videos are available to help designers quickly understand the potential of TI’s CapTIvate™ technology and master its use. TI also provides reference designs and development boards that further showcase the flexibility and power of CapTIvate™ technology, and these can serve as a great launching point for interface design.

• The TI MSP-CAPT-FR2633 CapTIvate™ MCU development kit is an easy to use evaluation platform for the MSP430FR2633 microcontroller that allows engineers can quickly turn up proof of concept designs and easily begin development of their device architecture.

TI’s MSP-CAPT-FR2633 Captivate Development Kit

• The Low-Power Touch Through Glass reference design showcases an HMI solution for harsh and hazardous area applications. It leverages the CAPT-FR2633 MCU module to allow easy connection of four PCB-implemented capacitive buttons behind a 10mm thick glass window in a screw-down metallic enclosure. The design allows safe control of industrial processes without requiring shut-down or special measures to ensure personnel safety during programming.

• The TIDM-CAPTIVATE-64-BUTTON ultra-low-power touch panel reference design also interfaces to the CAPT-FR2633 MCU module from the development kit, and uses mutual inductance to enable all 64 buttons to be tightly packed and controlled with only 16 MCU pins. Single touch and multi-touch are supported at over 100 samples per second, and average power consumption is as low as 1.75 μA per button with low-power optimization and 0.23 μA per button with wake-on-touch mode enabled.

TIDM-CAPTIVATE-64-BUTTON

• The TIDM-CAPTIVATE-THERMOSTAT-UI demonstrates a thermostat user interface with a low power profile, low response time, and good noise immunity. Eight capacitive touch buttons are included, and each supports momentary or maintained switch operation and is accompanied by an LED that can be used to indicate touch or switch state. Line-powered and battery-powered modes are available, with the battery mode consuming less than 50 μA on average.

TIDM-CAPTIVATE-THERMOSTAT-UI

TI Extended Range and High Precision Capacitive Sensing

For proximity and gesture applications that require higher resolution, faster sampling, or increased capacitive sensing range, the MSP430FR’s I²C interface can be connected to TI’s FDC2x1x family two or four channel EMI-resistant Capacitance-to-Digital sensors. The FDC2x1x line employs an innovative tunable narrowband architecture to offer high noise rejection while providing 12- or 28-bit resolution and sampling rates as high as 13.3 ksps. These devices operate by sensing changes in the resonant frequency of a driven LC tank, and the narrowband fundamental can be tuned from 10 kHz to 10 MHz to support a wide variety of applications. Power consumption is a low 2.1mA when active, and sleep and shutdown modes use 35 μA and 200nA, respectively.

The FDC2x1x family is ideal for human, object, and obstacle proximity detection up to 50cm, as well as collision avoidance sensors, Rain/Fog/Ice/Snow sensors, and automotive kick and door sensors. Liquid level detection is even possible for conductive fluids such as detergents, soapy water, and ink. The FDC2214 Noise-immune Capacitive Proximity Sensor design is a complete hardware and firmware solution that demonstrates the use of TI's capacitive sensing technology. The design processes the data from one proximity sensor and two capacitive touch buttons via the FDC2214 to determine whether an object is in the intended sensing area. Dedicated colored LEDs light up once the device detects a target in close proximity to the board or detects a press on the buttons. The design is powered by one AA-battery.

FDC2214 Noise-Immune Capacitive Proximity Sensor

TI Inductive Sensing Solutions

TI also offers several inductive sensing solutions with their LDC1312/1314 and LDC1612/1614, and LDC0851. These low-cost contactless sensors do not require magnets, are insensitive to environmental contaminants, and offer sub-micron resolution to ensure reliable operation, even when the electronics are located remotely from the sensor. The LDC1612/1614 28-bit inductance to digital converters are ideal choices for inductive knob controls, linear and rotational encoders, buttons, keypads, and sliders, and support metal detection and flow metering. Like the FDC product family, high noise immunity and support for a wide variety of applications is enabled through the use of a narrowband sensor that can be operated between 1 kHz – 10 MHz. The 12-bit resolution LDC1312/4 devices are cost- optimized versions of the LDC161x for systems that require lower absolute precision.

The LDC0851 differential inductive switch is ideal for contactless, close range applications such as presence detection, event counting, and simple buttons. The differential design ensures reliable and accurate switching and prevents false triggering due to temperature variations or the presence of magnets, dirt, oil, moisture, and other environmental contaminants. It also features high noise immunity and hysteresis to further ensure a reliable switching threshold that is immune to vibration and other sources of false switching. A simple push/pull output switches low when the sense inductance drops below the reference inductance, and returns high when the sense inductance is higher than the reference. This makes the part ideal for standalone use or use as an interrupt when connected to a GPIO.

Several reference designs for their inductive sensing solutions.

• The LDC0851 evaluation module allows quick and easy evaluation of a sensor that detects conductive objects passing in front of its stacked sensor coils. Sensitivity is easily adjustable via the included potentiometer, and an LED output provides visual indication of sensor activation without the need for an attached MCU.

LDC0851 Evaluation Module

• The TIDA-00508 1 Degree Dial reference design uses the LDC1314 to implement a magnet-free and temperature stable contactless rotational position sensor accurate to 1 degree using standard PCB technology and easily manufactured components.

TIDA-00508 1 Degree Dial Reference Design

• The TIDA-00828 32-Position Encoder Knob uses the TI LDC0851 to create an inductive sensing incremental rotary encoder design that provides a robust and low-cost interface for control inputs, and is scalable to support multiples of four positions per rotation. It requires no magnets and can reliably operate in the presence of environments which have dirt, moisture, or oil which would pose issues for other sensing technologies.

32-Position Encoder Knob

• For fan speed and event counting, the TIDA-00851-LDC0851 Event Counting reference design can measure over 300 events per second and like other LDC0851-based designs, requires no magnets and operates reliably in the presence of oil, dirt, and moisture. Several metal touch designs are also available.

• The TIDA-00314 Metal Touch Buttons with Haptic Feedback design provides a sealed metal enclosure with several metal button options for use with gloves, underwater, and in harsh environments. The amount of force needed to register a button press is programmable, and customized haptic feedback and waveforms provide an excellent user experience.

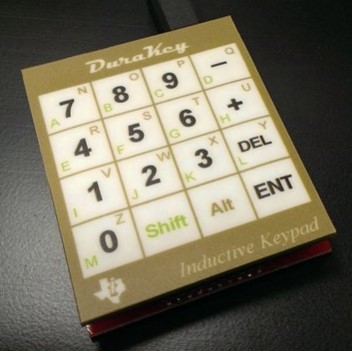

16-Button Inductive Keypad

TI offers the most comprehensive capacitive and inductive sensing HMI solutions in the industry. Their devices allow the rapid realization of reliable noise-immune sensing solutions that eliminate the wear and contamination problems that plague traditional mechanical interfaces and sensors while enabling elegant designs that seamlessly blend glass, plastic, wood, and metal surfaces.