Widely used in automation, robots, autonomous guided vehicles and drones, ultrasonic sensors are common in a range of applications. This article will show you the principles and applications of ultrasonic sensors, as well as the ultrasonic sensor solution introduced by CUI Devices.

Ultrasonic sensors have the advantages of flexibility and low cost

Ultrasonic sensors have been commercially available for decades. Due to their capabilities, flexibility and low cost, they will continue to occupy a very large share in the sensing market. The sound waves emitted by ultrasonic sensors are usually between 23 kHz and 40 kHz, much higher than the typical audible range of human hearing at 20 kHz. Thus, they are called ultrasonic waves. The distance between the transmitter and the object can be calculated by measuring the time required for the sound to bounce off the object as long as the transmitter emits ultrasonic waves.

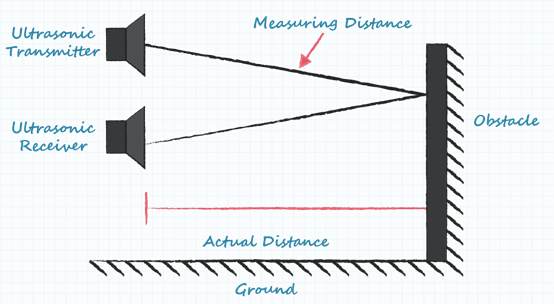

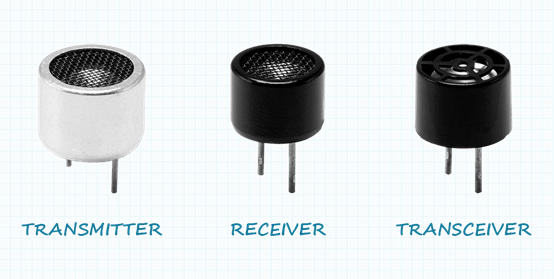

Ultrasonic sensors need two parts: a transmitter and a receiver. In the most standard configuration, they are placed side by side as close as possible. When the receiver is close to the transmitter, the sound will propagate in a straighter line from the transmitter to the detected object and back to the receiver, resulting in smaller measurement errors. There are also ultrasonic transceivers, which integrate transmitter and receiver functions into one unit, minimizing physical errors and significantly reducing the PCB footprint.

Basic operation of an ultrasonic transmitter and receiver pair (Source: CUI Devices)

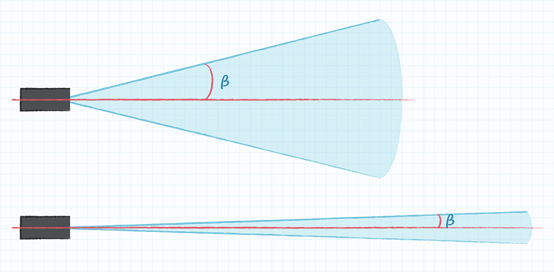

The sound wave leaving the transmitter is more similar in shape to the light leaving the flashlight than the laser, so spread and beam angle must be considered. As the sound wave moves away from the transmitter, the detection area will expand laterally and vertically. The area is changing because the ultrasonic sensor gives its coverage specifications in terms of beam width or beam angle instead of a standard detection area. When comparing this beam angle between manufacturers, it is recommended to verify whether or not the beam angle is the full angle of the beam or the angle of variation from the straight line from a transducer.

Understanding the beam angle is essential for establishing the detection area (Source: CUI Devices)

Beam angle is very important to establish the detection area

The ultrasonic beam angle also affects the detection range of a device. In general, a narrow beam will produce a larger detection range, because the energy of ultrasonic pulse is more focused and can travel farther before dissipating to an unusable level. Conversely, a wider beam will spread energy into a wider arc, thus reducing the expected detection range. Choosing an ideal beam width depends on the application to a great extent. A wide beam is more suitable for covering a larger area and general detection, while a narrower beam can avoid false alarms by limiting the detection area.

When searching for an individual component, the ultrasonic sensor can be obtained as an independent transmitter and receiver or as a combination of the two in a single unit, which is called an ultrasonic transceiver as discussed above. Most analog ultrasonic sensor options are actuated by sending a trigger signal to the transmitter with the receiver sending back a signal when the echo is detected. The designer can customize the length of the pulse and any encoding as needed. This process ultimately leaves the time calculation between trigger and echo, as well as the decoding, to the host controller.

The onboard digital ultrasonic sensor module calculates the distance and then transmits the distance to the host through the communication bus. Although ultrasonic transmitters, receivers or transceivers are usually purchased separately and assembled with custom circuitry and firmware, they are also sometimes available as a single unit, pre-mounted on a PCB with standard ranging configuration and simple logic board. Although it is simpler to use, designers do give up a great deal of flexibility and customization by using these modules.

Advantages and disadvantages of ultrasonic sensors

As with any technology, ultrasonic sensors are most suitable for use in certain situations or applications, but not in all other situations. The advantages of ultrasonic sensors include being unaffected by the color of the objects being detected, including translucent or transparent objects such as water or glass. In addition, their minimum and maximum ranges are quite flexible, with most ultrasonic sensors capable of detecting as near as a few centimeters up to approximately five meters. Specifically configured modules can even measure up to nearly 20 meters.

With decades of use, this mature technology is very reliable and easy to understand, yielding consistent results. Ultrasonic sensors provide relatively precise measurements, errors usually within 1%, and even more precision if desired. They can make many measurements per second, yielding quick refresh rates. In addition, they are usually quite cheap because they do not need rare materials. Moreover, ultrasonic sensors can resist electrically noisy environments and most acoustic noise, particularly when using modules equipped with encoded sound waves.

Although ultrasonic sensors are a versatile technology, several limitations shall still be taken into account before making a final sensor selection. As the speed of sound is dependent on temperature and humidity, ambient conditions may change the precision of the measurements. Although the detection area is three dimensional, an ultrasonic sensor only detects that there is something a certain distance from the detector and cannot provide feedback on where the object is in the sensing area nor any features such as shape or color. Although ultrasonic sensors are relatively small in size and can be easily integrated into cars or industrial applications, they may be too large for very small embedded projects. In addition, like any sensor, they may get dirty, wet, or frozen, which will cause them to be erratic or non-functional. Due to their dependence on sound, which in turn depends on certain medium, ultrasonic sensors cannot work in a vacuum.

Ultrasonic sensors provide accuracy and reliability

Ultrasonic sensors can be used to detect the distance and proximity of objects. A non-contact method is adopted to provide simple “there/not there” logic or to accurately measure the exact distance from objects, so it is ideal for distance detection sensors in sweeping robots and other applications.

Examples of an ultrasonic transmitter, receiver, and transceiver (Source: CUI Devices)

For different application requirements, CUI Devices has introduced a series of ultrasonic sensors with various specifications, with a rated distance of 0.2-18m, and a series of transmitters, receivers and transceivers with analog output are provided as options. The ultrasonic sensor is mounted in a compact aluminum or plastic cases, with a through-hole mounting option and a beam angle of 75 degrees or 80 degrees. With a rated frequency of 23-40 kHz and a rated voltage of 80-180 Vdc, these ultrasonic sensors can provide accurate measurement in various detection, distance and proximity applications.

The ultrasonic receiver is used to convert ultrasonic waves into electrical signals. CUI Devices’ ultrasonic receiver has a beam angle of 75 degrees or 80 degrees, a rated distance of up to 18 meters and a rated frequency of 39 kHz. CUI Devices’ ultrasonic transmitter is used to convert electrical signals into ultrasonic waves, with a rated distance of 18 meters, a rated frequency of 23-40 kHz and a beam angle of 75 or 80 degrees. CUI Devices’ ultrasonic transceivers integrate transmitting and receiving functions into one package, providing users with simplified solutions for distance measurement, object detection and proximity sensing.

Conclusion

Although ultrasonic sensors are a well-known technology, they are still very important in many industrial and consumer applications. Their simplicity, low cost, and robust build make them an excellent choice for many new products requiring presence detection or distance measurement in a range of applications.