Learn more about the NMP series of modular power supplies in this article from MEAN WELL.

What’s more, as today’s world becomes increasingly digital, electronic systems are now including more embedded processing that can interface with modern supplies for the purpose of checking things like system voltages, current consumption, control power paths, and reading fault status.

The NMP series of modular power supplies by MEAN WELL allow for higher flexibility, more power in a configurable package, and access to a wide variety of features that provide assistance with system troubleshooting and monitoring, all while increasing safety and improving reliability.

The Power of Flexibility

MEAN WELL offers two max wattages in the NMP series, 650W and 1200W, while their modular, output modules each provide up to 240W at a variety of industry standard voltages, including 5V, 12V, 24V, and 48V, with each adjustable to a wide range plus or minus the nominal and covers 3~55V applications with just four different part numbers. Additionally, the output currents are programmable and incorporate various levels of protection, including overload, over-voltage, and over temperature, as well as current sharing capabilities for parallel supply configurations.Most chassis-based systems operate from a variety of DC voltages. The NMP supplies can provide up to four slots for the 650W version, and up to 6 slots for the 1200W version, all fitting within a low-profile 1U footprint. Having these configurable slots makes it easy for future upgrades, add-ons, obsolescence management, and other things requiring flexibility and adaptability on voltage rails and power in the event of future changes.

Greater Peace of Mind

According to Intertek, a widely known certification company, it’s typical that half of all electronic systems fail EMC tests in one form or another in the first round of certification testing. This obviously causes a big waste of resources and time1. MEAN WELL has addressed this issue head on: the NMP series of supplies contain a number of safety approvals and ratings. This not only makes it easier to implement, it also lowers risk when launching new products. Leakage current is also a sore point for larger systems during regulatory approval, as each AC-related component adds some level of leakage current to a system, often putting them over the threshold. At an earth leakage current of less than 400uA at 264VAC (<100uA touch current), the NMP series is a significant improvement over the 1mA or greater typical values found in other supplies.Taking a Closer Look with Real-world Examples

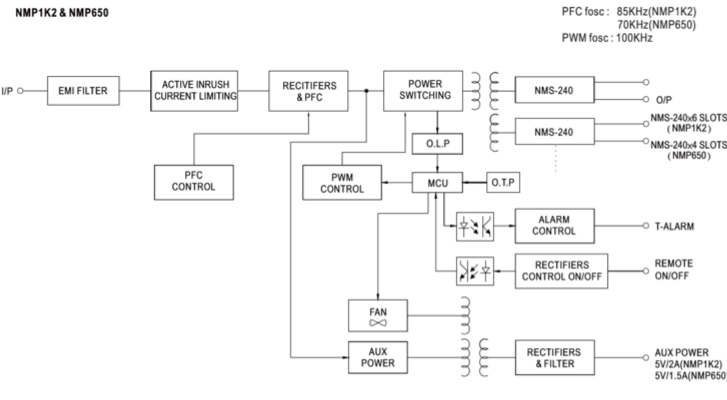

A digital interface for monitoring and control is core to the design of these NMP supplies, as seen in the diagram below2.

Figure 1. NMP Internal Block Diagram

The diagram in Figure 1 shows an embedded MCU that closely monitors temperature and provides variable speed control to a fan to eliminate unnecessary vibration and allow for a longer lasting cooling system. This is important in applications where vibration is critical, such as imaging or high-resolution motion control, where interconnect cables and mounting plates are almost always transmitting some level of vibration. It also greatly increases the life of the fan, a motorized component which often is one of the first things to fail in a power supply.

As seen in MIL standards such as MIL-HDBK-217, the failure rate of fans are some of the highest values compared to most other electro-mechanical components. According to the Mean Time Between Failures (MTBF) simulations and data within these MIL standards, the fan always seems to be the number one failure point in a system. Closed-loop cooling control only uses the fan as much as its needed, increasing the system’s reliability.

In addition to temperature, it also provides the capability for remote on/off control, as well as DC OK and temperature fault signals. Global and local on/off control can be very useful in energy-efficient systems, as well as systems sensitive to power up sequences or products containing low-voltage on/off switches tied directly to the power supply.

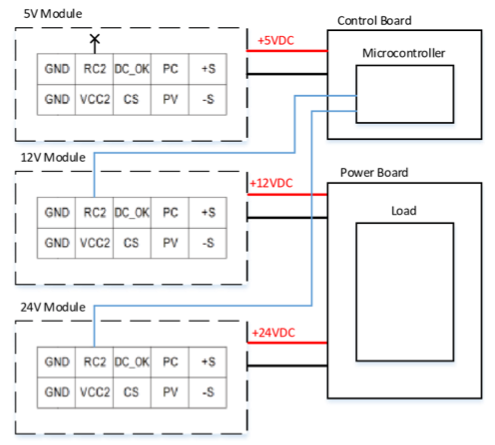

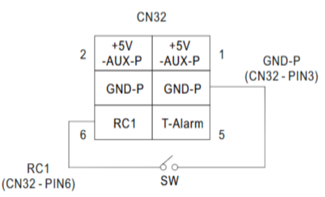

Figures 2 and 3 demonstrate ways to take advantage of this remote on/off control feature. You can either shut down the entire power supply via the 6-pin connector on the front or shut down each output module via the 10-pin connections in the back.

Figure 2. Power sequencing output modules with a microcontroller

Power sequencing is commonly done in systems requiring an extra level of safety and surge protection, or if particular boot-up timing requires it. The above figure shows a microcontroller turning on via the 5V module, and then once initialized, powers up each other output module in a safe state. This could help in applications where large loads are connected and have the possibility of defaulting in unsafe states in the first few milliseconds of system initialization.

Figure 3. Global power switch

In the event that the user needs access to a global power switch either for normal use or emergency stop conditions, a simple low voltage switch could be used on the global enable signal for the entire supply.

Along with the digital features found in these supplies, there is also a remote sense feature that helps when voltage drop is crucial, output voltage and output current programming via an external DC analog source, a current sharing pin that allow for balanced current sharing when using parallel supplies, and an auxiliary 5VDC connection for various uses.

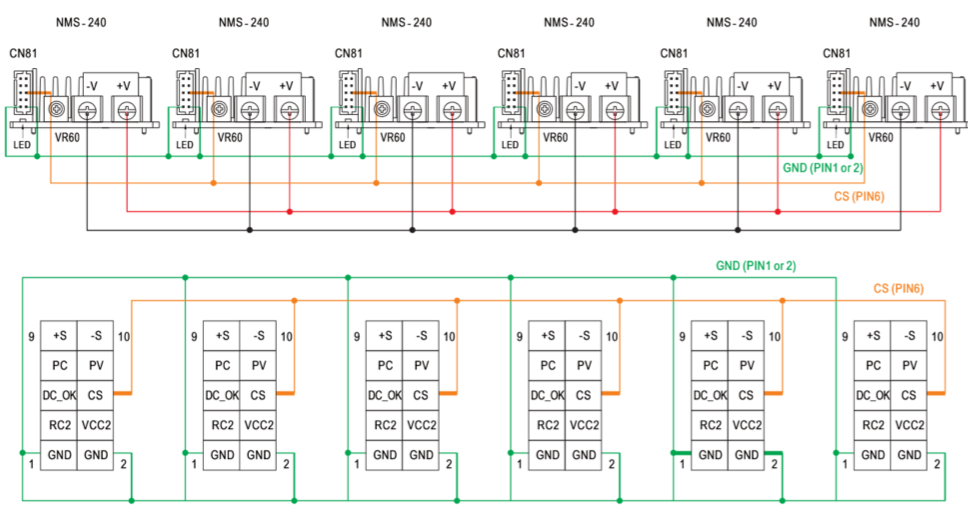

The current sharing feature is a great way to boost max current output at the same voltage rail. This can be useful for applications such as motion systems needing large in rush currents for high acceleration. For instance, if you needed 650W at 24VDC, you could use all 4 slots for the 24VDC module and tie the CS pin and ground together from the control interface, along with the V+ and V- rails. The same could be done for the 1200W 6-slot module, as shown in Figure 4.

Figure 4. Current sharing with several NMS-240 output modules3

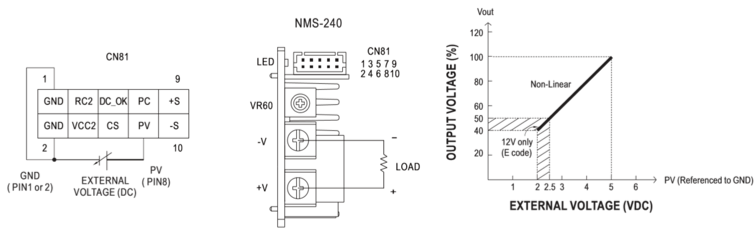

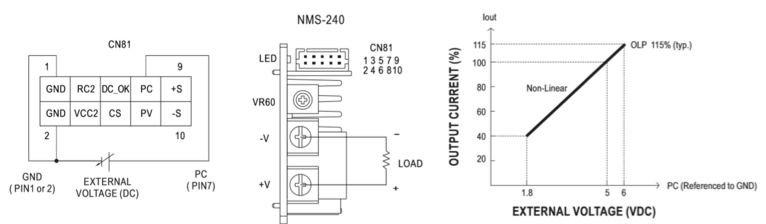

Programmable output voltages and currents are commonly found in applications such as motion control, environmental control, and sensing systems requiring specific power rails or current limits for components like lasers, motors, or heating elements. Tweaking the output voltage/current on these output modules can be done statically or dynamically depending on the system requirements. If a Digital-to-Analog Converter (DAC) is used on an embedded board, it could provide a controlled reference voltage to either the PC or PV pins on the 10-pin connector as shown below. Voltage and current can be controlled 40-100% of the nominal output value. Figures 5 and 6 show voltage and current programming on the NMS modules4.

Figure 5. Voltage programming on the NMS-240

Figure 6. Voltage programming on the NMS-240

Where to Begin

These supplies are ideal for (but not limited to) medical and diagnostic equipment, or precision test and measurement systems requiring a high level of reliability and flexibility, low tolerances, and various levels of protection.

Contact Arrow’s sales team to learn how MEAN WELL’s NMP series supplies can help improve your design today.

1: Intertek White Paper – Why 50% of Products Fail EMC Testing the First Time

2: MEAN WELL NMP Series Datasheet, Page 5

3: MEAN WELL NMP Series Datasheet, Page 12

4: MEAN WELL NMP Series Datasheet, Page 10