The increasing number of battery-powered applications, especially for electric vehicles (EV) and portable devices (e.g., smartphones, tablets and power tools), has led to increasing global demand for batteries, which in turn, poses a greater need for battery management and energy storage. This article will show you the battery management system (BMS) and energy storage system (ESS), as well as related solutions.

BMS increases the efficiency of battery system

For all battery-powered equipment, it is necessary to manage the charging and discharging process of the battery, and different battery management systems are required by the number, capacity and power of the batteries. A battery management system is an electronic control circuit capable of monitoring and regulating the battery’s charging and discharging. Battery characteristics to be monitored include battery type, voltage, temperature, capacity, charging state, power consumption, remaining operating time, charging cycles, etc.

The battery management system is designed for guaranteeing optimum utilization of the remaining energy in the battery. In order to avoid loading the battery, the BMS system protects the battery from deep discharge and overvoltage as a result of extremely fast charging and extremely high discharge current. In the case of multiple-cell batteries, the battery management system also possesses the cell balancing function for management different batteries, allowing them to have the same charging and discharging requirements.

Taking the solution provided by Infineon as example, Infineon's chip and design can assist customers in the layout of the battery management system, and provide support in the whole design process according to the design considerations of battery protection and charging and discharging process monitoring, including providing different products, simulation tools and reference designs, to help customers overcome the design challenges and develop the battery-powered applications featuring greater efficiency, durability and reliability.

Infineon, in line with the customer's application restrictions, can check the different architectures of the battery management system to locate the supported product series of Infineon, such as multi module high-voltage battery, or single module medium-voltage battery (above 60V) or single module low-voltage battery (below 60V).

Infineon's BMS solutions can manage the parameter detection, performance evaluation, protection, switching, battery optimization, communications, data and event logging of battery cells/battery packs. In addition, Infineon also provides battery charging system, battery condition sensing, control and communication, current and isolation monitoring, high voltage switch, power management chip (PMIC), thermal control and management and cross-module wireless connectivity, to provide a full range of solutions for the battery management system.

ESS is an important component of renewable energy applications

Energy storage has been an integral component of electricity generation, transmission, distribution and consumption over the decades. Growing power generation from renewable sources is leading to dramatic changes in the electricity landscape. The energy storage system provides a broad range of technical approaches for management of our electricity supply and demand, allowing for the creation of a more resilient energy infrastructure and cost savings for utilities and consumers.

Battery-based energy storage system technology can provide clean energy from configured solar or wind facilities, allowing instant response to power outages. When installed at before-the-meter, the energy storage system stores energy "in bulk" and can be used in conjunction with renewable energy generation or transmission and distribution systems. In residential and commercial scenarios, the energy storage system operates in behind-the-meter.

The energy storage system consists of two main components, including the power conversion system (PCS) capable of AC/DC and DC/AC conversions, feeding electricity into the battery, charging batteries, or converting the energy stored in the battery into alternating current, and transmitting back to the grid. The suitability of the power device solution depends on the voltage and power flow conditions supported.

In addition, the above battery management system with battery charging, balance and health monitoring functions, as well as the microprocessor for system control and communication are required. The system provides basic components that enable the integration of the energy storage system (ESS) into large-scale systems.

With unique experience in energy generation, transmission, power conversion and battery management, Infineon is definitely the preferred partner to drive the development of energy storage solutions in terms of efficiency, innovation, performance and optimal cost. Infineon's products include discrete OptiMOS™, CoolMOS™, CoolSiC™ MOSFET and IGBT modules, as well as highly integrated 3-level Easy 1B/2B modules, functionally integrated EiceDRIVER™ gate driver IC, XMC™ controllers and security solutions, and are known as the preferred products in various energy storage system design.

Operating efficiency improved with SiC DC/DC converter

In the energy storage system, there are usually two kinds of structures; maximum power point tracking (MPPT) combined with bidirectional buck-boost converter and power conversion system (PCS), and MPPT combined with DC/DC converter and PCS. The difference is that the back end of the bi-directional buck-boost is connected to high-voltage batteries, while the back end of the bi-directional DC/DC converter is connected to low-voltage batteries.

Take bidirectional DC/DC converter as an example; DC/DC converter runs in double-quadrant mode, the polarity of input and output voltage remains unchanged, but the direction of input and output current can be changed. The bidirectional DC/DC converter, as typical "dual-purpose" equipment, can realize the bidirectional transmission of energy, and is equivalent to two single-phase DC/DC converters in terms of function. Bidirectional DC/DC converter can be generally divided into two types: isolated and non-isolated. Isolated bidirectional DC/DC converter is widely used, and the circuit topology has a variety of changeover forms. Isolated bidirectional DC/DC converter features various circuit topologies with own characteristics, and can be divided into different combinations of full-bridge circuit, half-bridge circuit, push-pull circuit, or different combinations of transformed circuit.

The full-bridge circuit is characterized by four identical switching tubes connected into a bridge structure, driving the primary side of the pulse transformer. Its advantages are reduced primary side windings and synchronous decrease in switching tube voltage resistance, but its disadvantages are relatively obvious, including the use of a large number of switching tubes and the requirements for better parameter consistency. The half-bridge circuit is similar to the full-bridge circuit, except that two switching tubes are replaced with two large equivalent capacitors.

The topological structure of the push-pull circuit is characterized by symmetry. In the primary side of the pulse transformer, there are two symmetrical coils, two switching tubes are connected into a symmetric relationship, and are turned on and off in turns, with operating process similar to that of class B push-pull power amplifier in the linear amplifier circuit.

At present, as a part of photovoltaic energy storage, most of the bidirectional DC/DC converters adopt the topology of conversion circuit, which are mainly CLLC and phase-shifted full bridge. Most of the power devices in DC/DC part is designed by IGBT, with switching frequency controlled at about 20K. The increase of switching frequency and the reduction of loss have been a difficult problem for hardware engineers. The DC/DC part design of pure SiC (silicon carbide) scheme developed by Arrow Electronics and chip manufacturers allows for a switching frequency up to 200K and efficiency up to 96%, which is worthy of reference for manufacturers in need.

Busbar improves both efficiency and safety of power distribution

As far as the power transmission of energy storage system is concerned, a busbar refers to the conductive copper wire or aluminum wire used in the distribution board, distribution box, substation, etc., of the power transmission and distribution system, in order to connect the lines with the same voltage. Amphenol IPC is one of the global leaders in the field of energy storage system power technology, with industry-leading engineering, design and manufacturing expertise.

Amphenol IPC's busbars are custom-designed to meet or exceed customer specifications. Amphenol IPC's expertise in a wide range of applications, materials and processes ensures that the right solutions are delivered to the customers.

Power distribution busbars, including aluminum, copper, laminated, printed circuit boards, flexible aluminum and flexible copper, are mainly used for low and medium DC voltages, with inductance usually playing a less important role. Power conversion busbars, including high temperature laminated, standard laminated, stacked and Intelligent laminated, are designed for medium to high AC voltage and low-inductance applications.

Compared to metal wire, a busbar is cheaper and more advantageous in large quantities. Improved assembly, handling and testing enables the improvement of reliability and the reduction of maintenance, and the improved electrical and mechanical properties (especially packaging) and enhanced thermal management make it the best choice for power transmission in the energy storage system applications.

PowerLug improves wiring safety and convenience

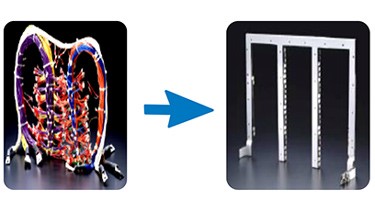

Connectors also play an important role in terms of busbar connection, where PowerLug can be used to redesign the power wiring of the power distribution unit (PDU). The PowerLug, as a new energy storage connector, is known as a pluggable solution for front and rear connection of the energy storage device, reducing 16 crimped connections and 6 bolted connections to just 4 PowerLug and operating temperatures down by 20°C.

The PowerLug connector from Phoenix Contact eliminates the need for tightening screws. Battery connections with PowerLug connectors can be directly pluggable, suitable for busbar connections and battery connectors, allowing you to install the energy storage system for applications up to 1,500 V in a quickly, safely and cost effectively manner. The use of pluggable interface reduces wiring effort by 75%, enabling quick installation and providing comprehensive touch protection even when not plugged in. Safe installation and maintenance and clear feedback during insertion ensure the highest level of safe and durable connections.

The device and PowerLug cable connector come with polarity-reversal protection, making it ideal for energy storage systems. Connectors with rotatable design, touch protection, and mechanical coding provide maximum flexibility and safety in the connection of battery terminals. The possible 360° rotation makes it ideal for flexible cable outlets. Mechanically coding battery connections prevent polarity reversal, avoid insertion errors, and prevent contact with battery terminals even when they are not inserted, improving installation safety.

PowerLug is available in a variety of color versions for easy identification of battery poles. Flexible installation methods, different device connection technologies and modular design allow it to be used in an increasingly number of diverse current applications. The plug-in system with integrated interfaces eliminates the need for wiring during installation. PowerLug is provided with the optimized special connection technology for use in storage systems, which are necessary for safe, reliable, and efficient connection.