With the maturity of silicon carbide (SiC) technology and the decrease of cost, SiC-based power modules are gradually becoming the standard in the power electronics industry, including electric vehicles, renewable energy and engine-based applications. This article will show you the technical development and market application of SiC and the product features of WolfPACK™ module introduced by Wolfspeed.

SiC technology has better performance characteristics

SiC has excellent high current processing performance and relatively lower loss at high switching frequency than silicon (Si), so it is a future-oriented semiconductor material. In order to make full use of the material characteristics of SiC, the power module will be able to improve the operation efficiency. The module removes excess packaging/interconnections wiring, which can realize compact circuits and improve thermal management performance, thus improving the efficiency of common topologies and contributing to faster installation and application.

Baseplate-less module technology has become a relatively mature multi-purpose package in the field of power electronics. Now, through many advantages brought by the combination with SiC technology, SiC can achieve a smaller size and optimize system cost without sacrificing efficiency and performance.

In addition, MOSFET and diode using SiC technology have been proven to meet all common design goals of car owners, businesses and municipal units in supporting fast off-board charging. Compared with other options currently on the market, SiC-based solutions generate less heat, are smaller in size, are more environmentally friendly, lighter, more durable, faster and more efficient.

SiC technology is more efficient and widely used

Taking electric vehicle charging infrastructure as an example, SiC technology can be used to minimize the size and weight of charging station while maintaining charging time and reducing overall losses, which enables charging stations to be integrated into various environments, thus starting to promote the popularization of charging stations, to reach the popularity of similar fuel-fired automobile gas stations in the future.

Suppose SiC technology is applied to solar energy solutions. In that case, the power generated by photovoltaic (PV) modules will fluctuate violently due to weather conditions. The power provided by these PV modules is a direct current, which must be converted into alternating current through solar inverters before it can be transmitted to the power grid for local use or to the point of use. Although this is a complicated process, the whole process can be simplified because the baseplate-less SiC module has higher efficiency in converting direct current into alternating current. In addition, the baseplate-less SiC solution can reduce the size, weight and cost of PV inverters by nearly 50% while improving efficiency.

In addition, baseplate-less SiC technology is also suitable for a series of non-automotive and motor-based applications, especially those related to electronically controlled motors. SiC-based power solutions can bring a smaller footprint to various types of motors and drive devices. They can be applied to AC and servo drivers such as industrial automation applications, including tool machines, logistics systems and robots. The main reason is that baseplate-less topology can achieve better thermal performance and improve scalability for these industries.

Moreover, SiC-based power modules are also suitable for supporting high-efficiency energy storage systems and double-conversion systems in uninterruptible power supply (UPS) systems. This is mainly due to modular design, which can form built-in redundancies and eliminate a single point of failure. Baseplate-less packaging can provide designers with higher efficiency, better thermal management performance and stronger reliability. Therefore, expandability can be realized and performance can be improved by stacking power modules, improving energy efficiency at a reduced purchase cost.

Efficient power module with flexibility and expandability

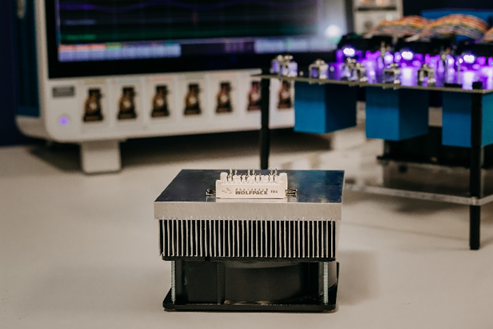

In order to meet the surging demand of the market, Wolfspeed, released Wolfspeed WolfPACK's new power module portfolio, which combines many advantages of SiC with the latest interconnect technology in a single and compact solution. Compared with several discrete, non-discrete and other commercially available modules on the market, the solution can maximize power per footprint.

Specifically, the new Wolfspeed WolfPACK power module family includes multiple SiC MOSFETs in a container, providing press-fit, solder-less pins for interface with an external PCB. The product provides optimized pinouts for specific applications according to the internal arrangement structure of MOSFET (such as half-bridge, full-bridge, six-pack integration, Buck/Boost layout, etc.), thus providing great flexibility and scalability for designers.

Unlike most high-current modules, Wolfspeed WolfPACK housing does not contain a baseplate at the bottom. It uses a ceramic substrate as an electrically isolated thermal pad , which is equipped with metal mounting tabs and can be used as a spring-force interface with the heatsink. The advantage of adopting this design is that it can evenly distribute the pressure to the bottom of the module and ensure sufficient thermal contact with the heatsink, thus providing a robust mechanical link between the heatsink, the module and the PCB. SiC technology enables high power density in small baseplate-less footprint package, and combined with a compact layout and simpler and faster switching, it can reduce the size of designers by nearly 25%.

Because Wolfspeed WolfPACK is a baseplate-less product, it is lightweight and can bring a smaller design size than traditional high-power substrate modules. In addition, Wolfspeed WolfPACK is an industry-leading SiC solution that can provide half-bridge and six-pack integrated configurations. Its application fields include electric vehicles, renewable energy, power grid, industry and many other application fields.

Conclusion

With the development of electric vehicles (EV), innovation in the power electronics market is continuously promoted. Other fields such as energy are also rapidly adopting more environmentally friendly power electronics technologies, thus reducing dependence on rapidly depleting natural resources. Higher efficiency SiC technology will promote the transformation of the industry towards SiC technology.

Wolfspeed WolfPACK module based on SiC technology can provide designers with solutions suitable for various applications (from single kilowatt design to megawatt systems). It can provide outstanding performance and provide excellent flexibility and scalability, making it a reliable and ideal choice for power electronics applications.