In many applications, such as automation machinery and automobile navigation, inertial sensors are needed assist in detection of the motion state of the devices. This article will show you the application and development of inertial sensors and related solutions introduced by ADI.

Inertial sensors provide critical accuracy and safety mechanisms

Whether in manufacturing, agriculture, logistics, energy, the automotive or unmanned aerial vehicles industry, mechanical automation can be achieved by a variety of sensor detection to significantly improve resources efficiency, equipment accuracy and safety.

At present, there are various sensors on the market, which can be classified into contextual sensors for sensing the environment, such as sensors that can sense temperature, optical, chemistry, gas and vibration, and position sensors for positioning, such as inertial sensor, GPS, magnetometer, barometer, ranging sensor, etc. By combining contextual sensors and position sensors, a complete Internet of Moving Things (IoMT) application environment can be formed.

In IoMT applications, positioning plays a key role. By pointing out a precise location or maintain accurate positioning, precision inertial sensors (or inertial measurement unit, IMU) will play a big role in it. In mobility-critical applications, the geolocating of the data captured by the contextual sensor needs to be determined. IoMT can fuse contextual data and positional data at the same time, greatly improving the value and benefit of data analysis.

The inertial sensor highlighted in this article is mainly used for detecting and measuring acceleration, tilt, shock, vibration, rotation and multi-degree-of-freedom (DoF) motion of the object and is an important component to solve navigation, orientation and motion carrier control. In most intelligent machines where GPS signal may be blocked resulting in inaccurate positioning and navigation, the inertial sensor can play two main roles; one is stabilizing and pointing of the devices, the other is to navigation and guidance, to maintain a reliable pointing angle of an antenna, crane platform, construction blade, farming implements or cameras on an unmanned aerial vehicle and other components and provide critical precision or safety mechanisms in harsh environments.

Industrial inertial sensors that strike a balance between cost and efficiency

At present, inertial sensors on the market usually adopt micro-electromechanical system (MEMS) structures. However, for certain MEMS structures with the main goal of reducing costs, performance is often sacrificed in design, e.g., by using consumer-grade products with reduced quality of silicon wafers and packaged in plastics, which have a great adverse impact on the performance of MEMS structures.

In order to extract accurate and stable information from MEMS devices, it is necessary to have a high signal-to-noise ratio, which is determined by the area and thickness of the silicon wafer. In addition, appropriate device packaging and system housing should be selected to minimize the stress on the silicon wafer. If performance requirements for end applications are kept in mind in defining the sensor at the beginning, and the silicon chip, integration, packaging, testing and calibration methods are then optimized, the original performance can be maintained in complex environments and the cost can be minimized.

In recent years, the role of noise in distinguishing sensor levels has decreased. In practice, industrial MEMS IMU and consumer-grade IMU are compared, both having better noise performance. However, consumer-grade devices are not designed or calibrated for vibration or alignment. It requires a high cost to improve accuracy by chip design method or device-specific calibration, while industrial devices achieve a better balance. Without considering other potential error sources with poor durability of consumer-grade products, the performance difference between the two is at least 20 times.

Cost-effective inertial measurement unit

In order to meet customer needs in high-precision inertial sensing applications, ADI has introduced a precision MEMS IMUADIS16505, which consists of a triaxial gyroscope and a triaxial accelerometer. Each inertial sensor in the ADIS16505 incorporates a signal conditioning function that optimizes dynamic performance. Sensitivity, bias, alignment, linear acceleration (gyroscope bias) and point of percussion (accelerometer location) of each sensor can be demonstrated through factory calibration, with the calibration temperature range from −40℃ to +85℃. Therefore, each sensor has a dynamic compensation formula to provide accurate sensor measurement under various conditions.

The ADIS16505 provides a simplified and cost-effective way to integrate accurate multi-axis inertial sensing technology into industrial systems, especially it is more advantageous when compared in terms of complexity and investment involved in discrete design. All necessary motion testing and calibration have been completed in the factory production process, which greatly shortens the system integration time. In navigation system, close orthogonal alignment simplifies inertial coordinate system alignment. Compatible serial peripheral interface (SPI) and register structure has a simple interface for data communication for data collection and configuration control.

The ADIS16505's triaxial digital gyroscope models support dynamic ranges of ±125°/sec, ±500°/sec, and ±2000°/sec, with operating bias stability of 2.3°/hr (ADIS16505-1), X-axis and Y-axis angular random walks of 0.13°/√hr, 1 σ (ADIS16505-1), and axis to axis misalignment error of ±0.25°. The supported triaxial digital accelerometer has a dynamic range of ±78.4 m/sec2, with operating bias stability of 26.5 m/sec2 (x-axis and y-axis), supporting triaxial delta angle and delta velocity output, programmable operation and control, automatic and manual bias correction control. Data ready indicator for synchronous data acquisition support external synchronization modes, i.e., direct, scaled and output. Internal sensors and flash memory can be self-test on demand. With single power supply (VDD) from 3.0V to 3.6V, and mechanical shock survivability of 14,700 m/sec2, it can operate in the operating temperature range from −40℃ to +105℃.

The ADIS16505 is packaged in a 100-ball ball grid array (BGA) package with a size of about 15 mm × 15 mm × 5 mm. It can be used in navigation, stabilization and instrumentation, unmanned and autonomous vehicles, smart agricultural and construction machinery, factory/industrial automation, robotics, virtual/augmented reality and IoMT.

Breakout boards and evaluation kits accelerate development process

To speed up customer product development process, ADI has also introduced various evaluation kits, including the ADIS16505-x/PCBZ breakout board, which provides a convenient way to establish a prototype connection between each ADIS16505-xBMLZ IMU model and the embedded processor platform. Each ADIS16505-x/PCBZ breakout board can also be connected to J1 of the EVAL-ADIS2 evaluation system.

The ADIS16505-x/PCBZ breakout board is only 33.25 mm x 30.75 mm in size, with convenient 16-pin (2x8), 2mm pitch connectors and 2.3 mm diameter mounting holes on each corner (4 corners), and there are three models, which can correspond to different IMU models.

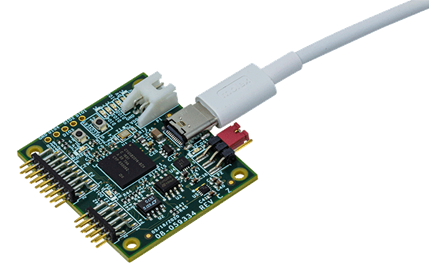

In addition, ADI has introduced the EVAL-ADIS-FX3 evaluation board, the latest member of the iSensor evaluation product family, which was originally designed to provide users with an easy-to-use solution to capture reliable inertial data in laboratory and characterization environments. The EVAL-ADIS-FX3 has the function of capturing inertial sensor data with maximum throughput, connecting with external test equipment and responding to external trigger signals.

In addition to the introduction of this reconfigurable hardware platform, ADI has developed a powerful API to help users quickly build custom applications that capture reliable sensor data. In addition, many useful functions are included in the API, which enables designers to characterize the performance of sensors in any .NET compatible environment.

The EVAL-ADIS-FX3 evaluation board can sample IMU in real time at full sampling rate, guarantee no data loss, do not need external power supply, and can also be powered through USB port. It has a fully open source API, firmware and evaluation GUI, and can provide schematics. API includes a wrapper library for interfacing MATLAB, Python and LabView. This evaluation board can be applied to inertial sensing, robotics, autonomous driving, platform stability and other fields.

Conclusion

Inertial sensors can be widely used in various positioning and navigation applications. As the cost is reduced and accuracy improved, market demand is rising. ADI offers factory-calibrated MEMS IMUs featuring high precision and high integration, and complete development and evaluation kits to speed up the product development process. They will become one of the best choices for related applications.